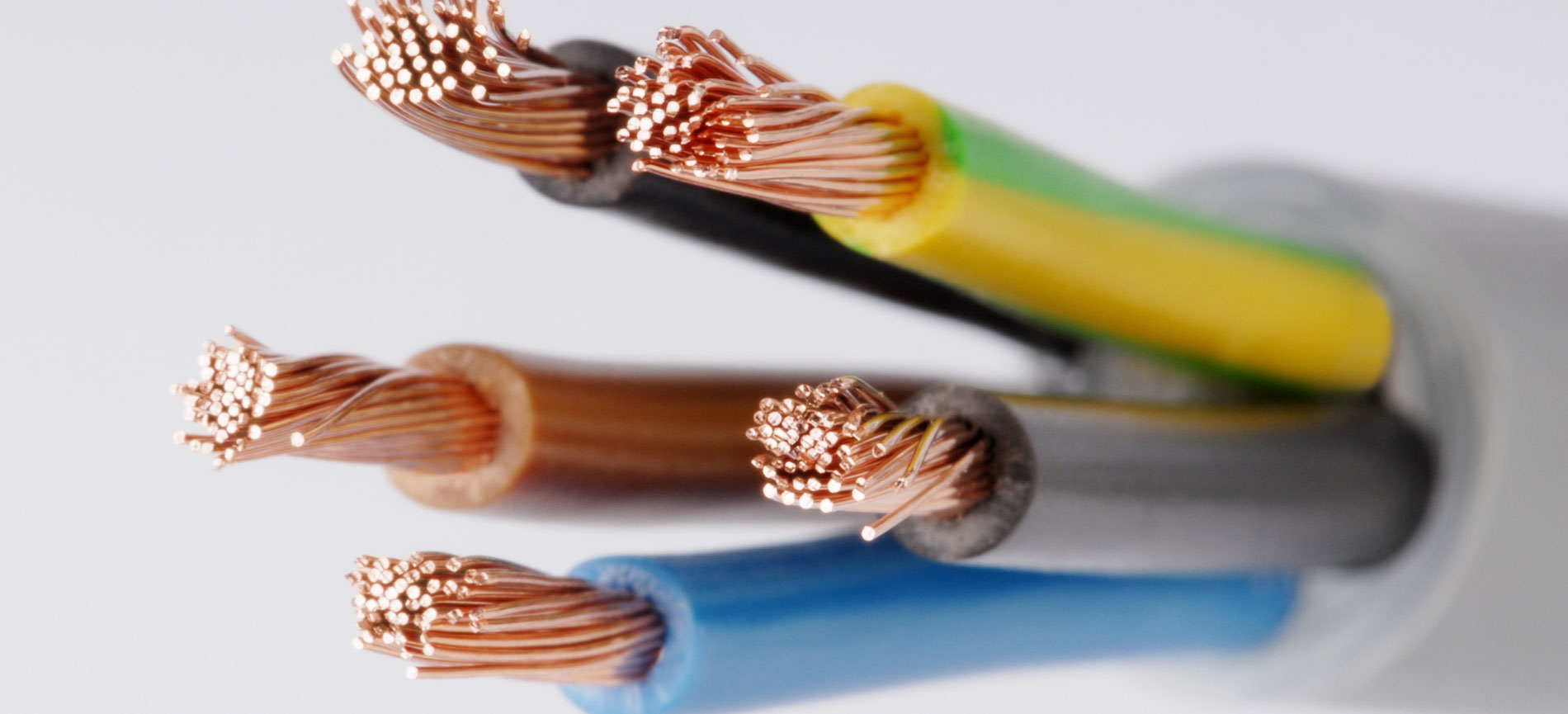

PolyPacific can satisfy the growing polyolefin and elastomeric material requirements of the Wire & Cable Industry with innovative and technically advanced compounds.

PolyPacific offers a range of polyolefin-based insulation and sheathing materials for electric cables designed to comply with AS/NZS 3808 requirements. This includes HDPE/LLDPE/LDPE grades, elastomeric grades, halogen-free flame retardant grades and silane cross-linkable compounds, curable by the addition of a catalyst and exposure to moisture (Sioplas® method).

Some of the applications related to this segment include electricity supply cables, telecommunications, automotive, transport and appliance.

We have a flexible approach and will work to develop compounds to meet specific customer requirements.

Current materials available include:

Insulation Compounds

PP based compounds –thermoplastic polypropylene compounds suitable for a maximum continuous operating temperature of 80°C. These compounds are easily processable and can be recycled.

PE based compounds –thermoplastic polyethylene compounds suitable for a maximum continuous operating temperature of 70°C. These compounds are easily processable and can be recycled.

X-90 –moisture curable silane grafted polyethylene compounds suitable for a maximum continuous operating temperature of 90°C. These grades are required to be extruded together with a catalyst masterbatch and exposure to moisture for the final article to be cross-linked.

X-90 UV –moisture curable silane grafted polyethylene compounds suitable for UV exposure and a maximum continuous operating temperature of 90°C. These grades are required to be extruded together with a catalyst masterbatch and exposure to moisture for the final article to be cross-linked.

R-E- 110 –moisture curable silane grafted elastomeric compounds suitable a maximum continuous operating temperature of 110°C. These grades are required to be extruded together with a catalyst masterbatch and exposure to moisture for the final article to be cross-linked.

Sheathing Compounds

HDPE based compounds –thermoplastic high density polyethylene compounds suitable for a maximum continuous operating temperature of 90°C. These compounds are easily processable and can be recycled.

LLDPE based materials –thermoplastic linear low density polyethylene compounds suitable for a maximum continuous operating temperature of 90°C. These compounds are easily processable and can be recycled.

PE based materials –thermoplastic low density polyethylene compounds suitable for a maximum continuous operating temperature of 70°C. These compounds are easily processable and can be recycled.

HFS-110-TP – thermoplastic, halogen-free, flame retardant, polymeric-based compounds having the characteristics of low smoke and reduced flame propagation properties and are suitable for a maximum continuous operating temperature of 110°C. These products are low smoke zero halogen (LSZH), do not contain any heavy metals and are easily processable on single screw extruders equipped with a low compression screws. They are also recyclable.

Both Insulation and Sheathing compounds include variants that are weathering resistant, have improved oxidative aging resistance or metal deactivation.